3D Printing

Tips

|

There are several basic steps to 3D

printing, including the transfer of a model file to the machine through

proprietary software, running the machine, curing and cleaning the model (or

vice versa) and then removing the supports. Beyond that, there are other

discrete and sometimes no-so-obvious tips and bits of advice that are good to

keep in mind. Here are a few of them, not in any particular

order:

Cleaning

Familiarize yourself with the specific

cleaning requirements of the material you are using, sometimes they are

extremely specific for a reason. In some cases the models cannot be soaked in

cleaning solutions or solvents, only rinsed. Soaking may cause warpage and

other model distortion. Or, if soaking is really necessary, there may be a

maximum time limit on the soak, beyond which the material might still be

damaged. Thoroughly reading and understanding all documentation about the

materials you use will be important to building good looking

models.

|

| |

|

| |

Materials

For building these

ship files into physical models, you will usually want to use material –

probably a resin – that has good strength and stiffness ratings (usually

listed as tensile strength and tensile modulus) and a moderate Elongation at

Break value. If the Elongation at Break value is too low, you may notice that

fragile elements break off easily when removing supports. If the Elongation at

Break value is too high, you may experience unwanted model distortion. WTJ

ships use as little plastic as possible in order to reduce overall warpage and

save you money on printing costs, this does mean that using the right material

for the build is key to a good model.

Here are some more detailed

examples; The DLP models made very affordably for several years at WTJ were

made with 3DS Tough-Gry 15. This material has a Tensile Strength of 7020 PSI, a

Tensile Modulus of 307 KSI, an Elongation at Break of 35% and a Shore Hardness

of 82D. These are good numbers that give the model excellent durability and

stability, while allowing removal of supports from under gun barrels without

excessive risk of snapping them off, although care still needs to be taken. If

you snip off gun barrels instead of carefully slicing them with a sharp blade,

the shock of the snipping action on such a small diameter can still overload

relatively tough material at any stress riser points; like the place where gun

barrels step-up in diameter. This is why if you snap a barrel, it often snaps

at that point where it steps-up in diameter or where it joins the turret

face.

The Print models also made at WTJ for many years had a Tensile

Strength of 6100 PSI, a Tensile Modulus of 212 KSI, and an Elongation at Break

of 7%. So while the print models had good general toughness via their tensile

strength, users did notice more of a tendency to snap barrels in casual

handling, and that would have mostly been due to the low Elongation at Break

value.

|

| |

|

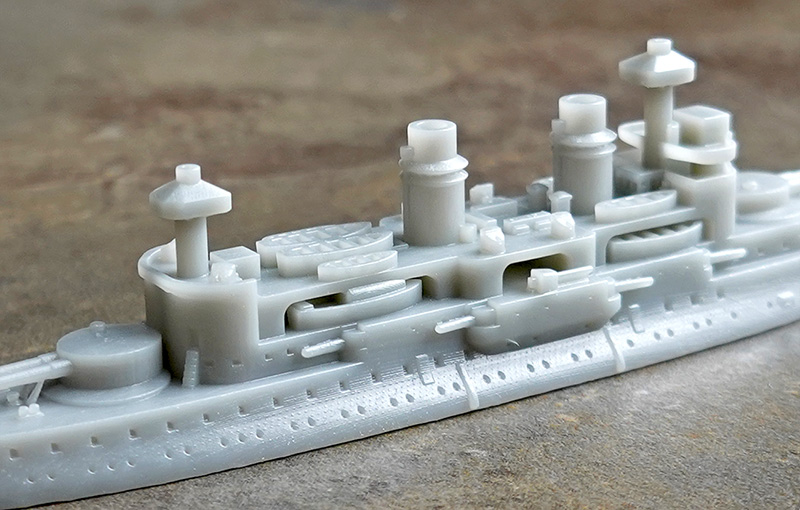

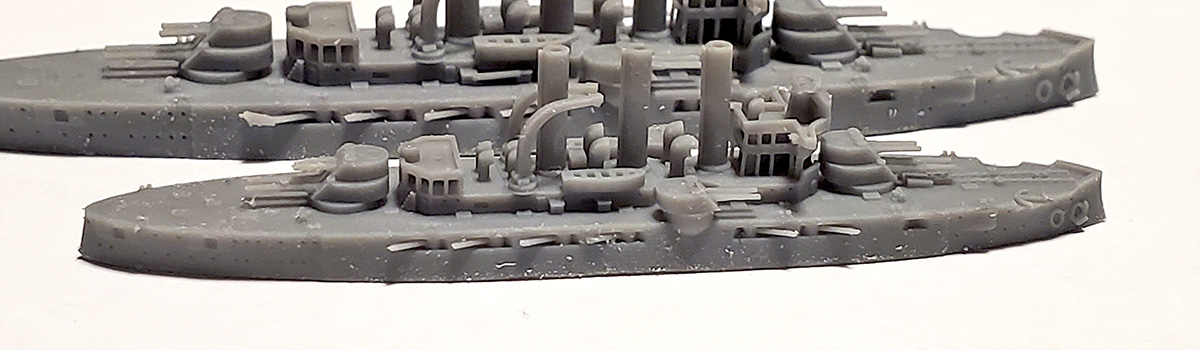

| The models above were

printed on a Phrozen Sonic 4k home printer using the Phrozen Aqua Grey 4k

resin. The foreground model is 1/2400 scale, the background model is 1/1800

scale, both were made from the larger 1/1250 scale digital file with free standing

gun barrels (the default 1/1800 file has fully supported barrels). |

|

| |

Supports

It is important that

overhanging features like gun barrels and cranes be supported correctly during

build. In the case of the 1/1800 scale WTJ file, the gun barrels will already

be fully supported by a solid boss. For the larger 1/1250 scale WTJ files, if

your printer software does not install supports under the barrels, they may

come out drooping or otherwise malformed. Be sure to review feature supports

before hitting the print button.

Removal - Removing supports must be

done at the right time. If the model is too soft before curing, removing major

supports may be easier, but removing the finer supports that are connected to

fine or delicate features may need to wait until after curing, when the

material can better handle the stress. The material requirements should be your

best guide for this. Check with the manufacturer or with online forums for

guidance on dealing with the material in question. |

| |

|

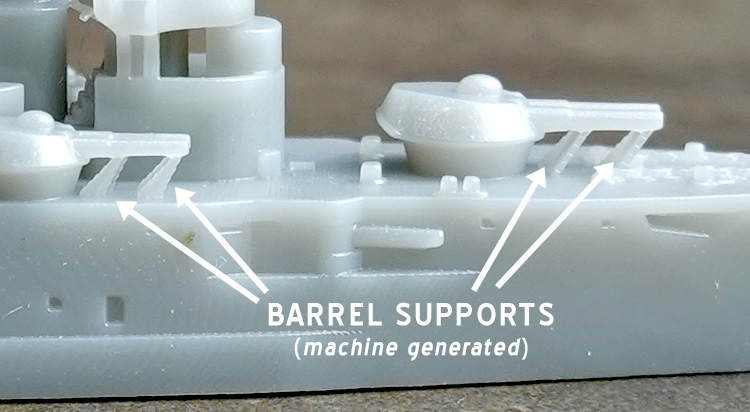

| This illustrates the gun

barrel supports typically installed by 3D Systems printer software (as opposed

to the solid supports included in the default 1/1800 file we sell). The

software-automated support installation is not always perfect, so it is best to

review it to make sure there is enough support and that the supports are in

sensible locations. |

|

| |

|